You might think soldered wires won’t stick so securely to something as thin as super thin ribbon LED strips, but as long as your solder is smoldering hot, and your wire ends get encased in the solder, it should hold perfectly!

Start by using a little sandpaper to sand down the contact points on your LED ribbon strip. This should make it easier for the solder to grip.

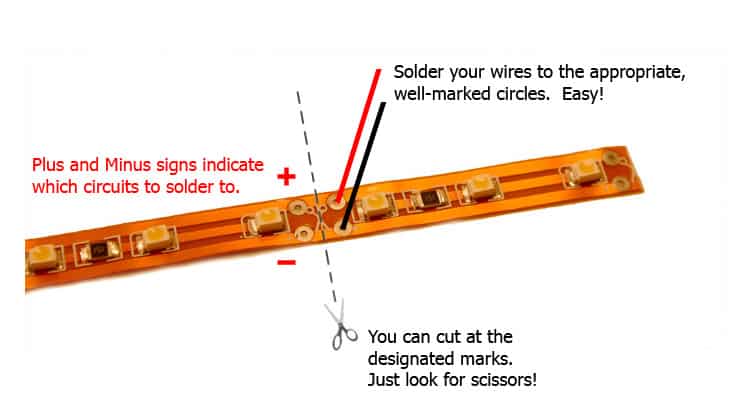

Heat the point that you’ll be connecting your wire to and apply your solder. You want it to be really hot, so it should melt and look almost bubbly.

Insert the wires so they are covered in solder.

Remember, when only one of the solder points is heated and the other is cold, we call this a cold solder joint. Cold solders don’t carry electrical current very well so it’s important that both points are nice and hot!

Extra Information

reddyuda

Ok so i bought the thin ribbon strips from oznium and the waterproof ribbon strips.

https://www.oznium.com/flexible-led-strips/led-ribbon

https://www.oznium.com/flexible-led-strips/thin-waterproof-ribbonThe points on my ribbon strips

DO NOT look like these:

User posted imageinstread they are completely filled. Solder WILL NOT stick to these points and im starting to get a little angry with how unintuitive this product is. It will BARELY hold on, but the second the wire is moved it breaks free. The same thing goes for the waterproof LED strips – but i cant even get to the points without striping the silicone insulation.Thank god this place has a decent return policy.

LED strip broke between solder nodes. Is there any advice on how to re-connect them without shortening the length of the strip?